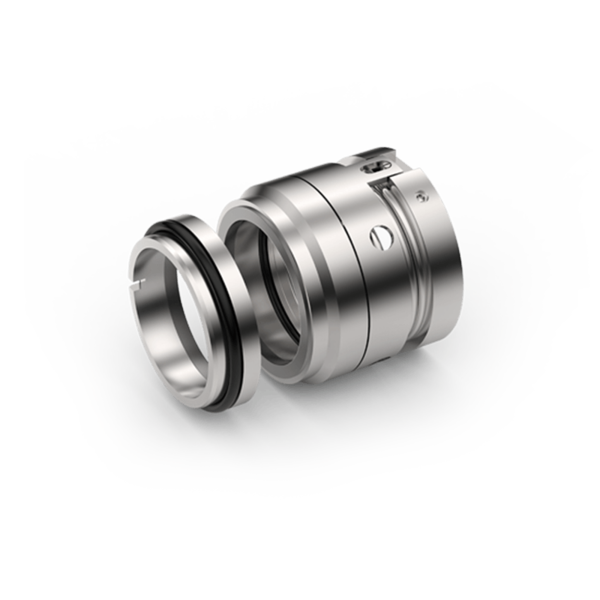

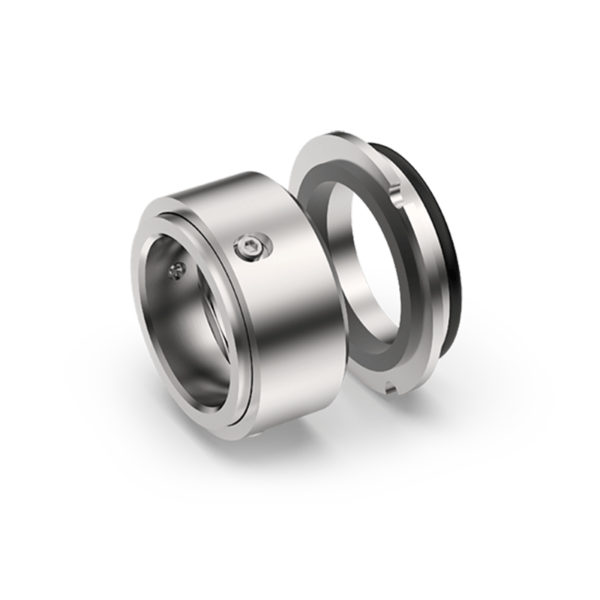

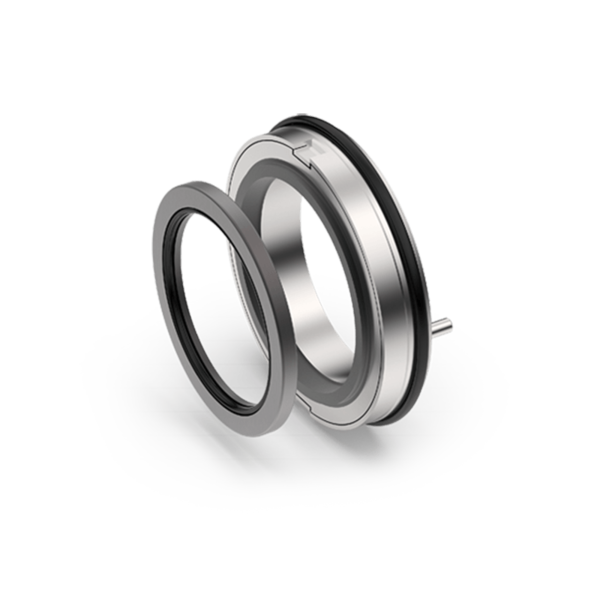

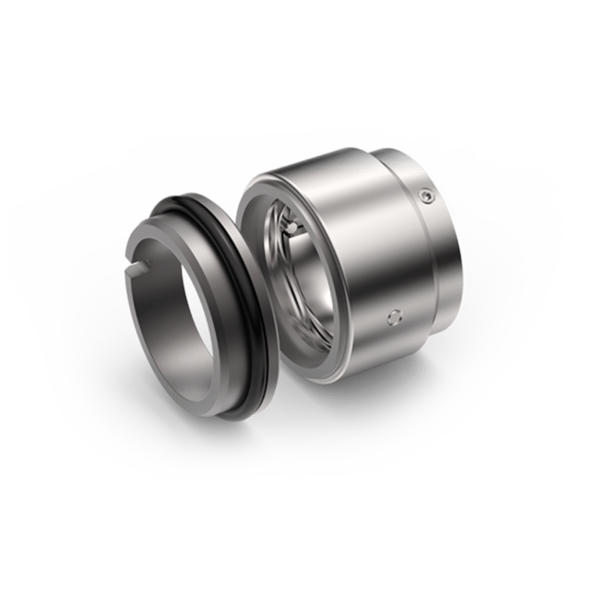

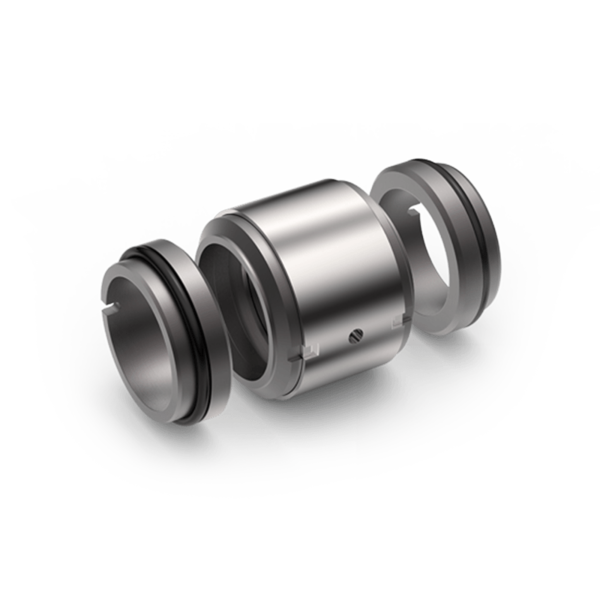

O-Ring Seals are a type of mechanical seal that are used to create a seal between two surfaces. They are typically made of rubber or other elastomers, and are shaped like a doughnut, or "O" shape, which gives them their name. The O-ring is compressed between two surfaces to create a seal, which prevents the leakage of fluids or gases.

O-Ring Seals are used in a wide range of applications, including plumbing, automotive, and industrial equipment. They are known for their simplicity, low cost, and versatility, as they can be used in a wide range of environments, from low-pressure and low-temperature applications to high-pressure and high-temperature applications.

O-Ring Seals are available in a variety of materials, including nitrile, silicone, and fluorocarbon, each of which is designed to perform well in specific temperature, pressure, and chemical environments. They are also available in different sizes and cross-sections to fit different applications.

O-Ring Seals are relatively easy to install and maintain, and they are relatively inexpensive. They can be used in static or dynamic applications and they are widely used in various applications such as automotive, aerospace, and the food and beverage industry.

It is important to note that the correct selection of O-ring seals is crucial for the proper functioning and longevity of the system. The installation, lubrication and maintenance of the O-ring seals should be done by experienced

O-Ring Seals Factory and in accordance with the

O-Ring Seals Manufacturers instructions and industry standards to ensure their proper functioning and to prevent any leakage.

英语

英语 西班牙语

西班牙语