Combustion Engineer Seals are responsible for designing, developing, and maintaining systems that are used to burn fuel in a controlled and efficient manner. As such, they may work with a variety of types of seals, depending on the specific application. Some of the types of seals that they may work with include:

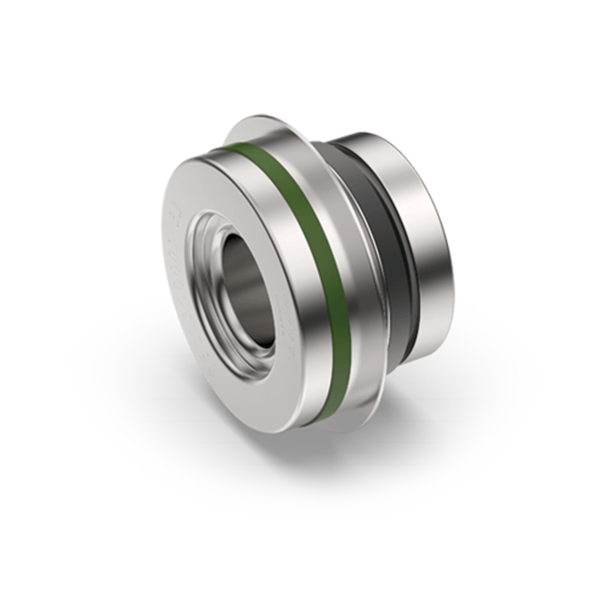

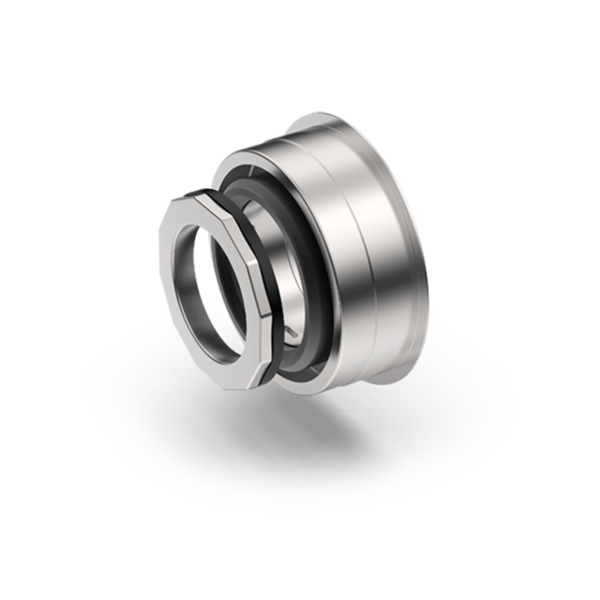

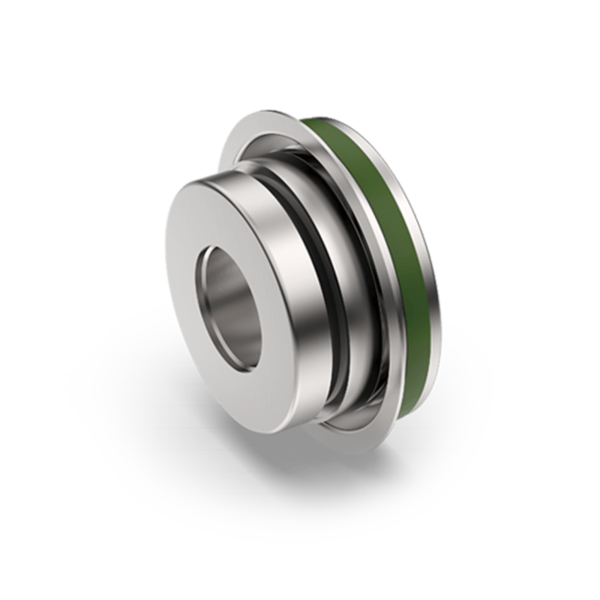

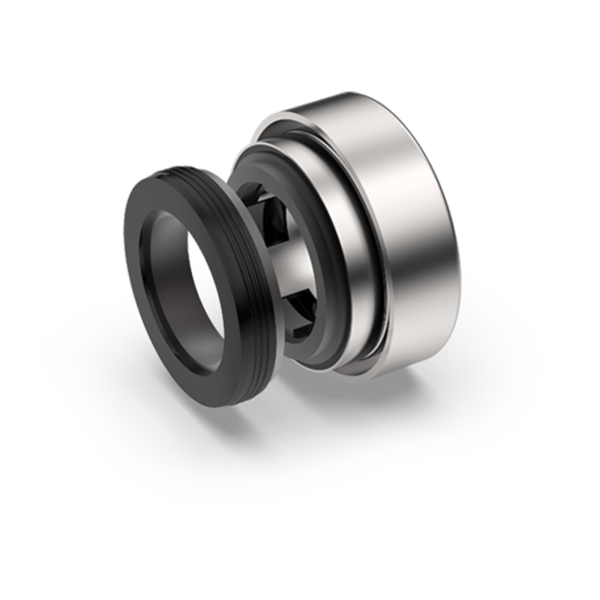

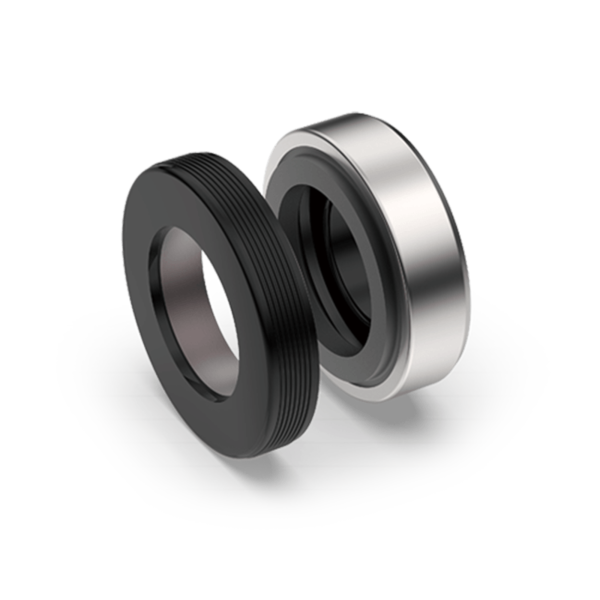

Mechanical seals: These are seals that use a mechanical barrier to prevent the leakage of fluids or gases. They are commonly used in pumps, compressors, and other types of machinery that require a tight seal.

Packing seals: These are seals that use a flexible material, such as braided rope or graphite, to create a barrier between moving parts. They are commonly used in valves and pumps to prevent leakage.

Lip seals: Lip seals are a type of rotary shaft seal that are used to prevent the leakage of fluids or gases. They are commonly used in applications such as combustion engines, gearboxes, and industrial equipment.

Fireproof seals: These are seals that are designed to prevent the spread of fire in the event of a combustion failure. They may be used in applications such as industrial boilers, gas turbines, and engines.

Combustion Engineer Seals will also work with other types of seals as well depending on the application, as seals have a huge role in the system efficiency and safety of the systems.

Combustion Engineer Seals Manufacturers will have to ensure that the seals are designed to be able to withstand high temperatures and pressures, and are made from materials that are resistant to the effects of combustion.

英语

英语 西班牙语

西班牙语